RECLAIMED STONE

Everything You Need to Know About Reclaimed Stone

The beauty of reclaimed stone begins with its history. Whether it’s stone blocks from an old bridge that crossed the Merrimack River for hundreds of years or stone pavers that lined Fenway Park during the early years of baseball—there is always a story behind reclaimed stone.

WHAT IS RECLAIMED STONE?

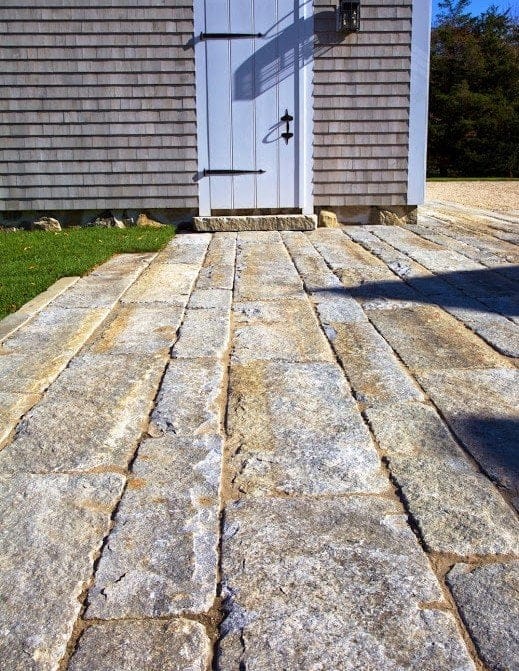

Reclaimed stone is sourced primarily from old roads and bridges, in addition to walls, buildings, and other structures which are no longer in use. This stone has been salvaged to be repurposed, sometimes as its current expression—old cobblestones from an alley in Italy become cobblestones on a private driveway—or it’s turned into something entirely different—bridge blocks become garden benches. The worn and weathered faces of the stone are reused as material for newly fabricated products: cobblestones cut thin to create floor tiles, bridge blocks sawn down to become capstones.

The ways in which reclaimed stone can be used to create new structures are endless.

Granite, limestone, and sandstone are the most prevalent reclaimed stone types, due to their wide use as building materials during the Industrial Revolution. Unsurprisingly, granite is the most common reclaimed paving stone type. This is because it’s so hard. But other hard regional stones were also used for paving, such as brick paving blocks in the Midwest, and porphyry and sandstone cobbles from Europe.

Over the past ten years, reclaimed stone has seen a surge in popularity. As we saw with reclaimed wood, reclaimed stone has also become a leading material for sustainably-minded architects and designers to include in their eco-friendly plans. Its unique antique appearance and patina, plus its specific history, offer up a beauty to new structures that cannot be recreated with quarried stone.

50% of the stone we source is reclaimed.

WHY CHOOSE RECLAIMED STONE?

We love reclaimed stone for so many reasons:

THE HISTORY — it can’t be faked. Reclaimed stone has a story behind it. For example, we recently sourced cobblestone from Auburn, Maine which once had the Ringling Brothers and Barnum & Bailey Circus parade over them.

THE WEATHERED LOOK — Rain, sleet, and snow create a natural patina on reclaimed stone that cannot be artificially replicated.

THE FEEL — Friction from walking or driving on stone surfaces creates a worn, softer texture, with a unique sheen, like the worn tops of cobblestone.

SUSTAINABLE — Make your project eco-friendly, reduce waste and negative environmental impacts by using reclaimed stone—hello Leed points!

UNIQUE — Machines are used to try to replicate the look and feel of reclaimed stone but they fall short of the real thing.

Using reclaimed stone is a wonderful way to contrast a modern design. Reclaimed curbing, for example, can be repurposed in a multitude of ways due to its length—fabricated into coping, large pavers, light posts, benches—the list goes on! Cobblestones can be reused in different orientations: tops up (as their original) or wide side up (for coping)—exposing the preferred surface (smooth from decades of wear or rough from the buried-side surface). Reclaimed stone is perfect in landscape design to help create a timeless feel—it looks like it’s been there forever, perfectly placed.

RECLAIMED STONE IS ECO-FRIENDLY

Like with anything, when you reuse, you reduce your negative impact on the environment. The same is true with stone.

Reclaimed stone is the eco-friendly, sustainable option for many reasons:

- It takes less carbon to reclaim stone than it does to run the machinery to quarry new stone since it involves less heavy extraction machinery and fabrication equipment.

- Locally-sourced reclaimed stone reduces carbon emissions from shipping.

- Green points are awarded through the Energy and Environmental Design (LEED) rating system.

- Shipping reclaimed stone from Europe and Asia container ship has a relatively low carbon footprint compared to other shipping methods.

- It’s a perfect example of upcycling!

WHERE DOES RECLAIMED STONE COME FROM?

Reclaimed stone becomes available when buildings, bridges, roads, and the like are deconstructed. Old world cities, where cobblestones and natural stone curbing were used for roads and buildings, become today’s sources for reclaimed stone. US East Coast and Midwest industrial cities, where the bricks and natural stone were used to build factories, mills and municipal buildings, provide additional sources for reclaimed stone.

Reclaimed European cobblestones dwarf what’s available in the US. Tens of thousands of miles of cobblestone streets were once covered with layers of asphalt when they were paved over after World War II. Modern road construction standards do not permit this—cobblestones must now be removed prior to a road being reconstructed. A similar situation happened in China, as they used natural stone for millennia for paving roads.

Due to the sheer volume of reclaimed paving stones available from Europe and China, the price is lower than in the US, although recent import tariffs are closing this gap.

Curbing generally needs to be replaced if a roadway is widened or reconstructed. Many reclaimed bricks and pavers come from the deconstruction of old building—notably old factories and mills along the US East Coast and the industrial Midwest.

Reclaimed Stone from

Roads & Bridges

Reclaimed Stone from Roads & Bridges

• Cobblestone

• Curbing

• Sewer hole casings

• Bridge blocks

Reclaimed Stone

from Buildings

Reclaimed Stone from Buildings

• Veneer

• Foundations

• Sills

• Lintels

• Quoins

• Landings

• Water tables

• Shingles

Reclaimed Stone

from Agriculture

Reclaimed Stone from Agriculture

• Millstones

• Grinding wheels

• Well covers

• Troughs

• Fence posts

• Columns

RELIABILITY OF RECLAIMED STONE

With any natural material recently quarried, there’s always the risk of discoloration or cracking—regardless of how small it is.

In reclaimed stone, if something like iron oxide (rust) was going to leach from the stone, it would have happened already. Therefore, the risk of further leeching is almost non-existent. Similarly, if cracking was going to occur in reclaimed stone, it would have already happened. Basically, if these were going to be problems, they most likely would have occurred in the prior life of the stone.

This is also true with harvested stone. For example, newly harvested fieldstone might have been covered for millennia. Once uncovered it may leach iron, but this may not happen for years after installation. On the other hand, reclaimed fieldstone from an old wall, for example, would not present this risk as any leaching or staining that was going to take place would have already happened.

Generally speaking, reclaimed stone can be structurally more reliable than recently quarried or harvested stone.

Reclaimed stone can be structurally more reliable than recently quarried or harvested stone.

WHAT TO KNOW BEFORE

YOU BUY

RECLAIMED STONE

When you’re deciding what type of reclaimed stone to use for your project, dig deep:

- What’s the story behind the stone? There’s always a story and it’s often fascinating. It may end up connecting you or your client more to the stone.

Understand the intended function of the reclaimed stone. Not every stone type can be used for every project. For example, not all reclaimed products can be repurposed for a patio where high heel shoes will be worn or for low heat absorption. Once we understand the intended function of the project, we can guide you on the suitability of various reclaimed materials and products.

- Each stone is unique and a work of art. You can’t pick out one perfect sample and expect the whole lot to look exactly the same. This inherent concern usually turns out to be what makes reclaimed stone so great—all the individual stones blended together look fantastic!

- Generally, reclaimed stone is not the least expensive product. The extra handling to find, harvest, sort, and transport makes this a handcrafted process versus a streamlined and efficient manufacturing process, so it can cost a bit more.

OUR RECLAIMED STONE

The most common reclaimed stone products are curbing, pavers, cobblestone, and wallstone.

Large bridge blocks are also highly sought-after. Reclaimed stone can also be repurposed, through hand-crafting or machine fabrication, to create a myriad of different stone products.

Reclaimed curbing, for example, which can come in up to 12‑foot lengths, was originally used as curbing and is now used as steps and landings. However, now we can fabricate it into all types of products—from oversized pavers to wall and pool coping to wall veneer to benches to home and garden accents.

We work with many kinds of stone fabricators, based on their capabilities and the project’s needs.

Our Featured Reclaimed Stone Materials

RECLAIMED STONE DEFINITIONS

Curbing

First-generation Curbing

From 1860 or older. Generally, someone worked the stone by hand to a specific specification. It has a chunkier, more irregular shape.

Second-generation Curbing

Less handwork, but some.

Third-generation Curbing

Mechanically made, with precise saw blocks and large splitters. The end product is more uniform and true.

Cobblestone

Worn Side Up

The most widely used method of installing reclaimed cobblestone is worn side up. The original worn surface, the top of the stone, is installed above the ground. This type of installation produces the historical signature worn look of the old world reclaimed cobble.

Wide Side Up (Domestic)

This is an alternative installation where the cobblestone is turned on its side to cover more area and therefore becomes more cost-effective. In this case, the worn top is hidden on its side.

Full Bed – Half Bed – Thin Cut (European)

European cobblestones are sometimes sliced in half or cut thin for a more cost-effective installation.

Flat Side Up (European)

Sliced cobblestones can be installed flat side up, which produces a surface that can be walked on easily with high-heeled shoes.

Flat side, thin cut cobblestones are often used for indoor flooring installations.